3D-tulostusosat 3C-tuotteille

- SHD Precision Tech

- Shenzhen

- 3 päivää

- 5000 kpl/kk

Lyhennä toimitusaikoja.

Rakenna monimutkaista geometriaa.

Pienennä valmistuskustannuksia

Why Choose SHD For 3D Printing Service?

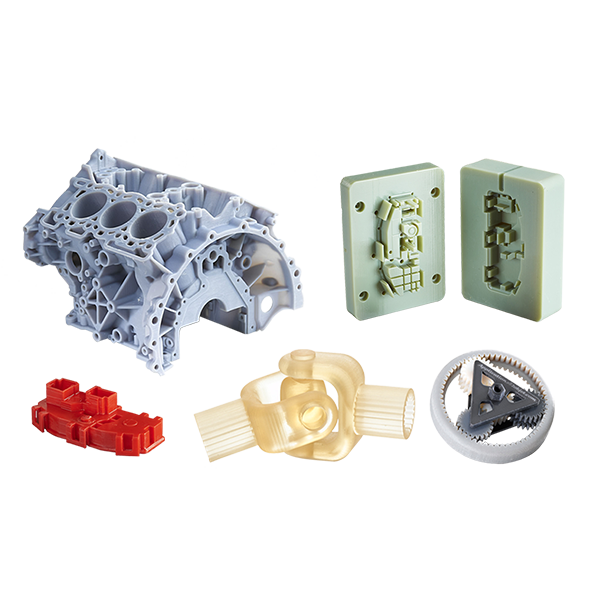

SHD is an expert in the field of rapid prototyping manufacturing in China, providing a wide range of 3D printing services, including SLA 3D printing (Stereolithography), SLS 3D printing (Selective Laser Sintering).

At SHD, We have a full team of dedicated engineers and project managers that will work with you to verify your CAD designs, product functions, dimensional tolerances, etc. As a professional prototype manufacturer, we deeply understand the prototype and production needs of any business. We strive to meet all specified times to deliver products with quality guarantees to our clients worldwide at affordable prices.

Benefits Of 3D Printing

Shorten Delivery Times.

Build Complex Geometry.

Reduce Manufacturing Costs.

Advantages And Applications Of SLA & SLS

SLA 3D Printing | SLS 3D Printing | |

Advantages |

|

|

Applications |

|

|

3D Printing Vs CNC Machining: Which Is Right For Your Prototype And Production : Part II

Subtractive & Additive Manufacturing

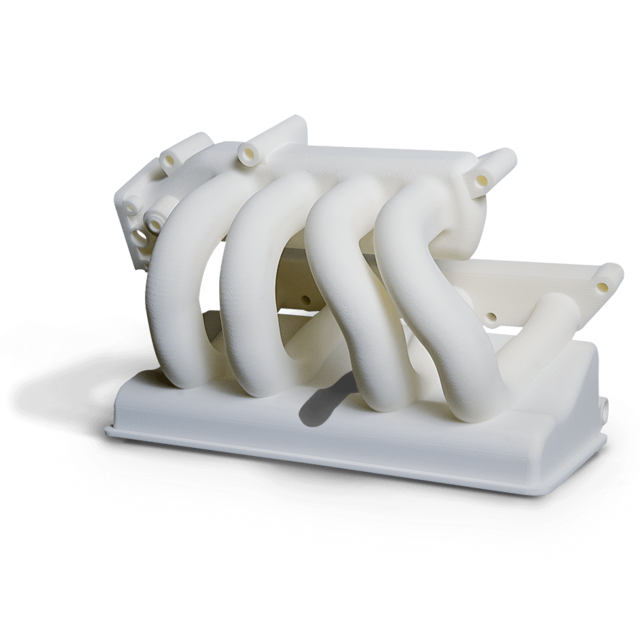

3D printing is also known as additive manufacturing, which builds parts through layers of materials. It has many advantages over traditional manufacturing processes however it has its problems. CNC machining is a fairly common subtractive technique used for parts manufacturing, which creates parts by cutting off the blank.Materials & Availability

The 3D printing process involves parts being created layer by layer using materials such as liquid photopolymer resins (SLA), drops of photopolymer (PolyJet), plastic or metal powders (SLS/DMLS), and plastic filaments (FDM). So it produces less waste compared with CNC process. CNC machining is to cut from a whole piece of material, so the utilization rate of the material is relatively low. The advantage is that almost all materials can be CNC machined, including production-grade engineering plastics and various metal materials. This means that CNC machining may be the most viable technique for prototypes and end-use mass-produced parts that require high functionality and special performance.